- 2025-10-25

What is a bilge pump? How does it work?

一、What is a bilge pump?

A bilge pump is arguably a core component found on any ship. This is also known as a marine bilge pump. To safely and conveniently drain sewage that accumulates beneath the ship's sump, these pumps are specially designed for underwater environments. While providing drainage capabilities, they can also pump other liquids and operate at temperatures ranging from -20°C to 140°C.

-20°C is suitable for low temperatures, such as seawater and low-temperature oil.

140°C is suitable for high temperatures, such as gasoline, diesel, and kerosene.

Learn more: Drainage pump design and working principle?

二、How does a bilge pump work? When should it be turned on?

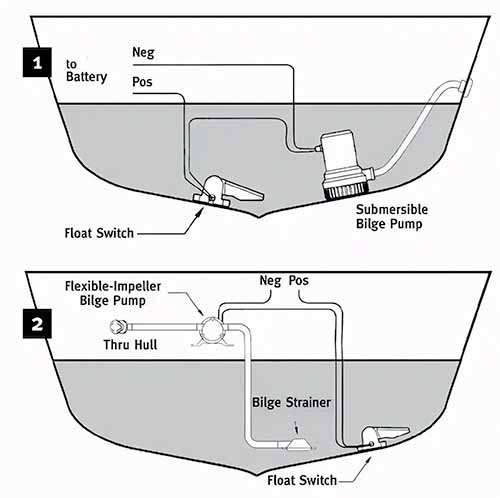

There are two bilge pump float switches: automatic and manual . When the water level reaches the set maximum, the float switch automatically activates drainage. When it drops to a safe level, the float switch automatically shuts off. Manual pumps are typically installed on small ships.

三、Where is the bilge pump located?

Bilge pumps are generally installed in different locations based on their type. Centrifugal bilge pumps are submersible and can only operate underwater, so they are installed on the bilge floor. Diaphragm bilge pumps are different; they need to be placed above the water surface, so they are located above the bilge floor. The hose of a diaphragm pump is located lower than that of a submersible electric pump, resulting in a higher displacement capacity. Bilge pump types are as follows:

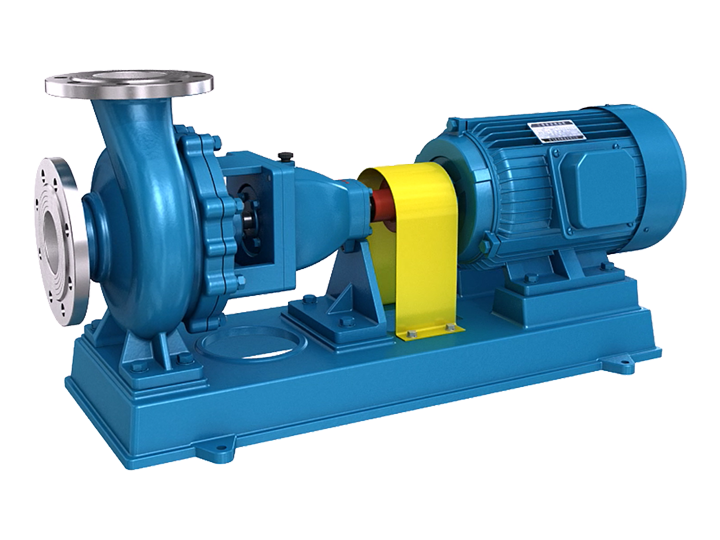

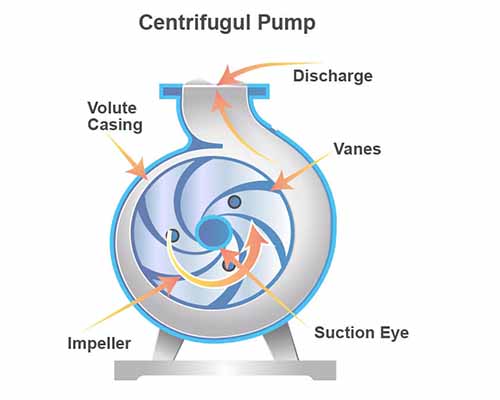

1. Centrifugal Pumps

Centrifugal pumps are electrically driven and horizontally designed. They are acid-resistant, alkali-resistant, and corrosion-resistant, making them particularly suitable for use on ships. They use centrifugal force to continuously draw in and out liquids. Therefore, they are the most commonly used type of bilge pump.

Advantages of Centrifugal Pumps:

Suitable for mildly corrosive liquids

Easy maintenance

High flow rate

High head

Wide range of applications

Disadvantages of Centrifugal Pumps:

Easy maintenance

High flow rate

High head

Wide range of applications

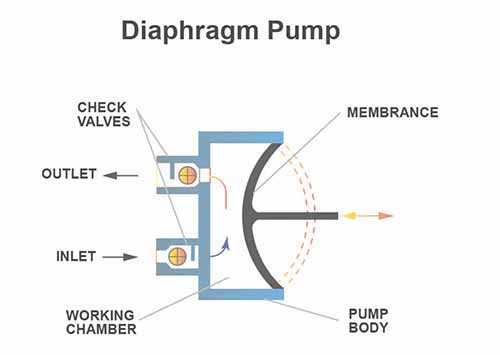

2. Electric Diaphragm Bilge Pumps

Electric diaphragm bilge pumps are self-priming positive displacement pumps. A motor, through a reduction gear, drives a diaphragm on two pistons, moving back and forth, drawing in and out accumulated water. The advantage of a diaphragm pump is that it's better at moving water upward than a centrifugal pump, allowing it to drain accumulated water at high flow rates. Diaphragm bilge pumps have a longer service life than most centrifugal pumps. There are various types of diaphragm bilge pumps, including single and double diaphragm pumps, and you can purchase one based on your environment.

四、Bilge Pump Maintenance

1. Regular Inspections

To ensure the proper operation of the pump and its associated components, regular inspections should be performed.

Inspect the following:

Bearing condition, seal integrity, motor operation, and any abnormal noise or vibration. Inlet and outlet ports should also be monitored for leaks, blockages, and other signs of damage.

2. Timely Part Replacement

Parts are particularly susceptible to wear and aging after extended operation. Pay special attention to bearings and seals. Replace them immediately if performance deteriorates or damage is observed. Additionally, timely cleaning and lubrication of key components not only prolongs the pump's lifespan but also ensures efficient operation.

五、 What is the service life of a bilge pump?

With proper maintenance, a bilge pump can have a service life of over five years. Choosing a high-quality pump when purchasing, along with proper operating environment and maintenance, can also maximize the pump's lifespan.

It's important to note that users should select the appropriate pump model and maintenance plan based on their actual conditions and needs to ensure long-term, stable operation of the pump.

六、Does a bilge pump need a filter?

A bilge pump filter is installed at the intake of the bilge water system to intercept impurities and particulate matter in the water, preventing them from clogging the pipes or damaging the pump, ensuring proper operation. Without a filter, debris can enter the pump, causing malfunctions or wear, potentially leading to accidents. Therefore, be sure to carefully inspect the pump before setting out at sea.

If you have any further questions, please feel free to contact us.