- 2025-07-16

Reservoir

Reservoirs | Water Treatment and Reverse Osmosis Systems

Water treatment facilities typically include several key components and processes that work together to purify and treat water. The specific configuration and equipment selection will be adjusted according to the size of the facility, its location and the water quality characteristics of the source water.

In the agricultural market, we apply water treatment technologies including ultrafiltration systems, water disinfection systems, nanofiltration systems, reverse osmosis systems and industrial filtration systems.

The water treatment process generally covers the following basic steps:

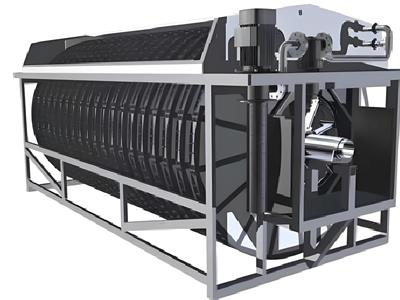

First, the water intake system extracts raw water from a natural water source such as a river, lake or underground well, and usually removes larger debris through a screen or grid to prevent clogging of subsequent treatment equipment.

Next, in the coagulation and flocculation stage, chemicals such as aluminum sulfate (alum) or ferric chloride are added to cause suspended particles to clump into larger flocs, which require gentle agitation to improve the effect.

Then, in the sedimentation stage, the water is allowed to settle in a sedimentation tank or clarifier, allowing the flocs to settle to the bottom to form a sludge layer for subsequent removal.

The filtration step uses media such as sand filters, activated carbon filter beds or membrane technology to further remove residual suspended solids and impurities.

Disinfection is essential, and common methods include chlorination, ultraviolet irradiation or ozone disinfection to kill harmful microorganisms and prevent the spread of diseases.

Depending on the water quality requirements, pH adjustment may be achieved by adding lime (to increase pH) or sulfuric acid (to lower pH).

For specific needs, advanced treatment processes such as reverse osmosis or activated carbon adsorption can also be used to specifically remove contaminants such as iron, manganese, arsenic or nitrates.

Finally, the treated water is stored in a clear water reservoir and distributed to the user end through a pipe network system.

It is important to emphasize that the actual treatment sequence and process details will be adjusted according to the type of water source (surface water, groundwater or recycled water) and the target contaminants to ensure that drinking water safety standards are met.

Key elements in water treatment storage facilities

As a core component of the water treatment system, water treatment storage facilities are responsible for storing treated water before delivery to end users, especially during peak water consumption or treatment interruptions to ensure stable and reliable water supply.

Key elements of these facilities include:

Water storage tanks or reservoirs: As large water storage containers, their size and design need to match system requirements and local conditions. They are usually built with materials such as concrete, steel or fiberglass and are located at high altitudes to maintain water pressure.

Inlet and outlet structures: The inlet is connected to the water outlet of the treatment plant and is equipped with flow control valves and filters to regulate inflow and intercept impurities; the outlet is connected to the water distribution network and manages the water output through valves.

Overflow and drainage system: The overflow is used to safely divert excess water such as heavy rain, while the drainage system facilitates emptying the storage tank for maintenance and inspection.

Monitoring and control system: Integrate liquid level sensors, pressure instruments and remote monitoring equipment to achieve automated operation and water quality assurance.

Security measures: Cover physical protection (such as fences, access control), electronic monitoring (such as cameras, alarms) and operational safety facilities (such as maintenance channels, emergency equipment) to ensure water supply safety.

To ensure clean and reliable water quality, these facilities must strictly implement regular maintenance, compliance inspections and standardized operating procedures.