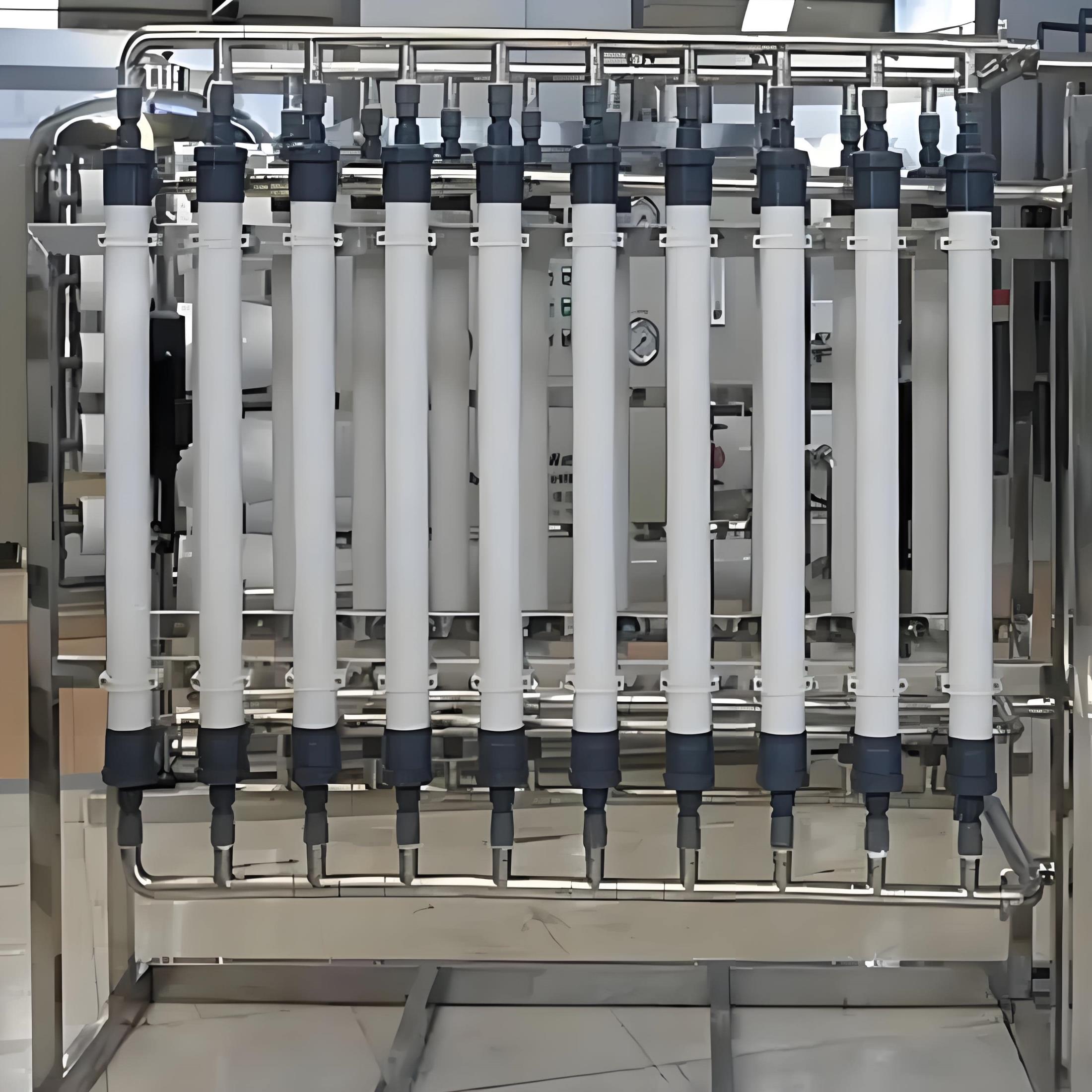

Ultrafiltration reverse osmosis equipment is a water treatment equipment that combines ultrafiltration and reverse osmosis membrane separation technologies.

FupengWater is dedicated to designing and manufacturing state-of-the-art ultrafiltration (UF) systems to meet the needs of diverse water treatment industries and applications, including chemical and pharmaceutical manufacturing, food and beverage processing, and wastewater treatment.

UF systems also have the following key applications in the water treatment industry for optimizing processes:

RO pretreatment

Graywater treatment

Water recycling

Water recovery

Drinking water treatment

In terms of system parameters, this UF system can handle turbidity levels up to 300 ppm. Equipped with UF modules of varying flux rates, it can treat water with total suspended solids (TSS) levels up to 100 mg/L.

As a global supplier of ultrafiltration systems with over 20 years of experience, FupengWater's products reliably remove suspended solids, turbidity, bacteria, pathogens, and viruses from water. These systems are economical, compact, and minimize clogging, while increasing solids loading capacity. Its ultrafiltration membranes offer extremely high filtration performance and high flux, along with excellent chemical resistance and tolerance to temperature fluctuations.

UF systems utilize various membrane filtration technologies, using hydrostatic pressure to propel a solvent through an extremely fine membrane. Larger suspended particles and solids are retained, while water and lower molecular weight solutes are allowed to permeate the membrane.

In industry and research, this separation process is commonly used to purify and concentrate solutions containing large molecules (10³-10⁶ Da), such as proteins. Ultrafiltration is similar to microfiltration, nanofiltration, or gas separation, differing primarily in the size of the molecules rejected.

To meet stringent discharge standards, efficient ultrafiltration systems utilize submersible, backwashable, and air-flushed membranes, eliminating the need for clarifiers and multimedia water filtration. Spiral-wound ultrafiltration/microfiltration membranes excel in purifying process water and wastewater.

Ultrafiltration (UF) membrane systems are more reliable than traditional multimedia filters. While traditional multimedia filters typically remove particles approximately 10 microns and larger, UF membranes have pore sizes ranging from 0.01 to 0.10 microns. In addition to excellent turbidity removal, UF membranes effectively remove bacteria and most viruses.

Excellent Filtration Performance and High Flux: Excellent filtration capacity and high flux.

Extremely Small Nominal Pore Size: Pore size is only 0.03 µm.

Effective Bacteria and Virus Removal: Excellent removal of bacteria and viruses.

Easy Maintenance: Occasional backwashing and air sparging improve performance and remove fouling layers, extending service life.

Low-Fouling Membrane Module: Membrane modules are less susceptible to fouling.

Optimized Configuration: UF with external or internal inlet configurations reduces clogging and increases solids loading. - Design Advantages: A basic, vertical, modular design enables a cost-effective and compact system.

Chemical and Temperature Resistance: Effective membrane cleaning with high chemical and temperature resistance.

Ultrafiltration systems use hollow membrane fibers to remove suspended solids, bacteria, viruses, and pathogens from feed water. A pump delivers the water to be treated through microscopic pores, which act as a physical barrier, allowing only the filtrate to pass through. Before entering the ultrafiltration system, the water is filtered through an ultrafiltration filter to remove solid matter such as weeds and plastics. Ultrafiltration equipment has long played a key role in water and wastewater treatment, consistently delivering excellent treatment results. Ultrafiltration-treated water can be fed to reverse osmosis systems for further purification or directly distributed to the public.

Ultrafiltration equipment is used in much of the world to ensure an adequate supply of clean water. Ultrafiltration systems can filter water approximately 250 times more efficiently than traditional media filtration systems. These systems are also well-suited for numerous industries requiring ultrapure water. Ultrafiltration membranes are used in devices to reduce turbidity or as a pretreatment to maintain the effectiveness of reverse osmosis membranes. These devices are generally considered to be low-cost, simple to operate, free of contaminant residues, and have fairly high recovery rates.

Power Supply: 460V/3Ph/60Hz

Temperature: 25°C (max. 40°C)

TOC: < 10, max. < 40 mg/L

pH: 6 - 9 (Cleanliness Level 2 - 11)

TSS: < 50, max. < 100 mg/L

Backwash Frequency: 20 - 60 minutes

Turbidity: < 50, max. 300 NTU

Cl₂: 0.5 ppm (2,000 cleanings)

COD: < 20, max. < 60 mg/L

Maximum Oil and Grease: 2 mg/L

Ideal applications for the FupengWater ultrafiltration system include:

RO pretreatment

Drinking water treatment

Water recovery and reuse

Greywater treatment

Process separation or recovery

Recycled water treatment

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD