- 2025-07-22

EDI Water Purification

Dissolved mineral ions in raw water often need to be deeply removed to meet industrial requirements. Deionization systems are mainly achieved through two technologies:

Ion exchange method: water flows through a highly charged resin bed for ion replacement

Electrodeionization (EDI): water flows through a selective membrane module driven by a DC electric field

The core difference lies in the regeneration method - traditional mixed bed deionization (MBDI) requires chemical regeneration, while EDI achieves continuous regeneration through electricity, and no chemicals are added during the whole process.

Technical positioning and application scenarios

EDI is not a substitute for traditional DI, but an optimized choice for specific needs:

Applicable to fields such as electronics and nuclear power that require ultrapure water with a resistivity of ≥18.2MΩ·cm

Avoiding chemical hazardous goods management: no need to treat acid-base regeneration waste liquid

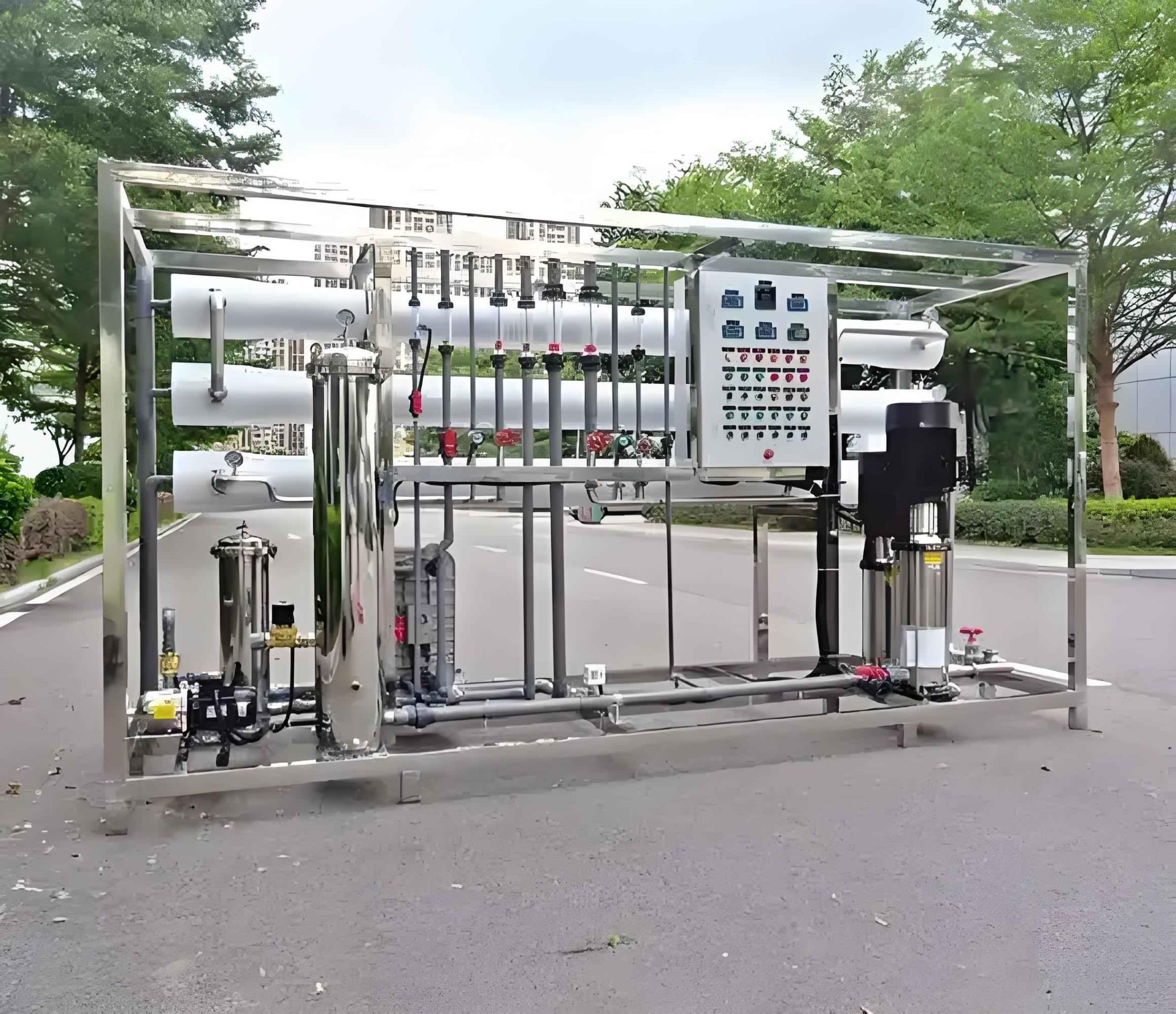

Must be used in conjunction with a reverse osmosis system: raw water cannot be directly treated

Core performance advantages

Continuous operation with zero chemical agent consumption

Stable output of 18.2MΩ·cm ultrapure water (traditional DI is difficult to maintain continuously)

TDS removal rate reaches ppb level

Irreplaceable in the fields of precision instrument manufacturing and laboratories

Key points of system configuration

As a deep processing unit, EDI has strict requirements for influent water:

Best water source: two-stage RO produced water (TDS<20ppm, hardness approaches zero)

Acceptable solution: single-stage RO produced water combined with softening pretreatment (eliminating the risk of hardness ion contamination)

Pollution control: Excessive hardness will cause scaling failure of the membrane stack

Equipment type selection guide

Plate-frame EDI

The structure adopts a multi-layer chamber electrode plate pressing design, similar to a plate heat exchanger. When water flows through the electrode interlayer, ions are selectively adsorbed and removed under the action of the electric field.

Roll-type EDI

Uses a spirally wound anion and cation membrane structure (similar to RO components), and ions migrate and separate in a directional manner under the drive of the electric field on the membrane surface.

Both types of equipment have built-in ion exchange resins, which achieve continuous self-regeneration through a DC electric field.