- 2025-07-22

Conventional Filtration vs Ultrafiltration

Traditional filtration process chain

For pollutants such as turbidity, color, iron and silica in drinking water sources, a five-stage treatment unit needs to be fully constructed:

Coagulation (adding aluminum salt/iron salt coagulant)

Flocculation (forming alum flowers that can settle)

Sedimentation (gravity separation of suspended solids)

Sand filtration (retaining particles ≥ 20 microns)

Disinfection (chlorine/ultraviolet inactivation of pathogens)

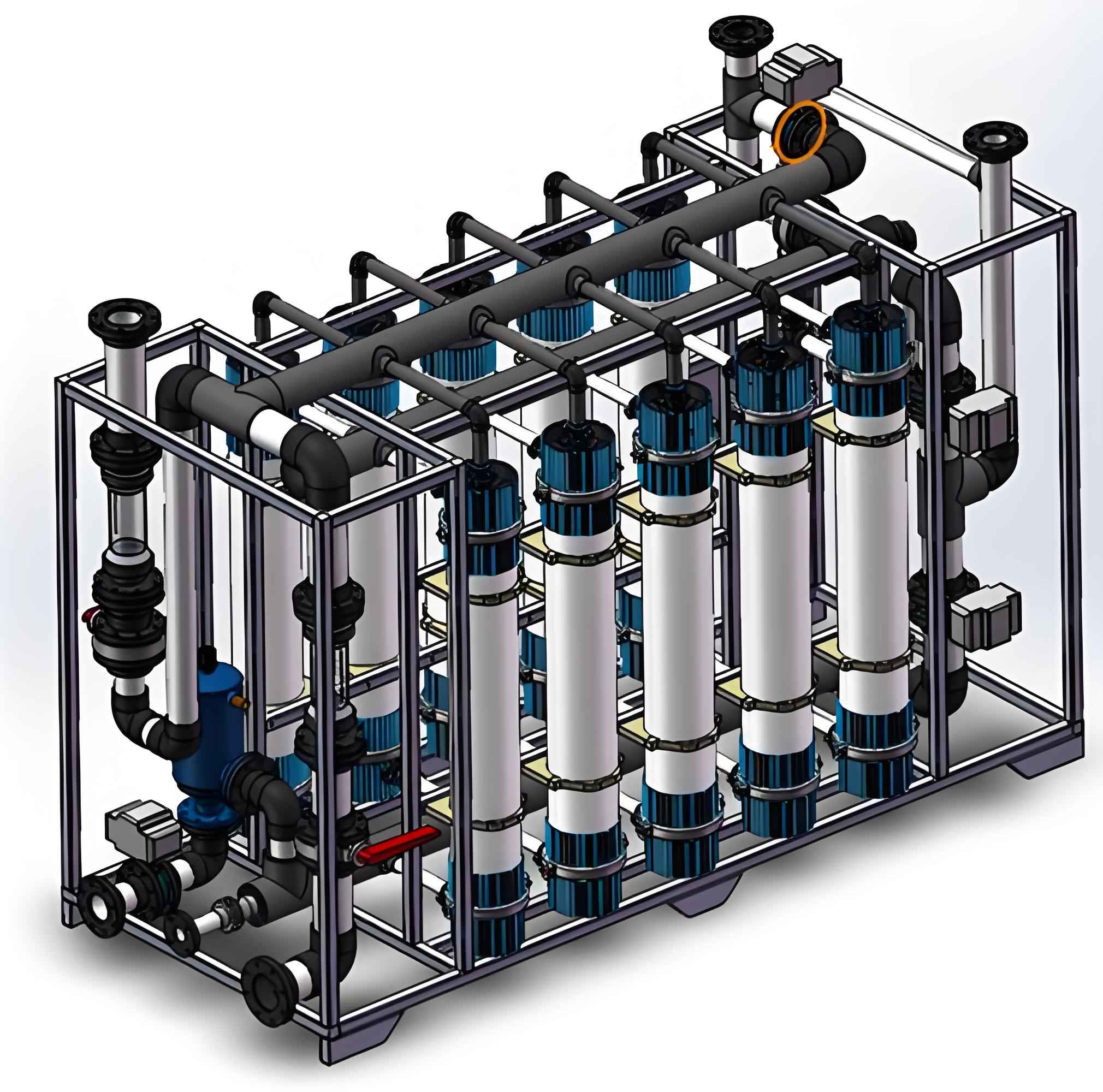

Ultrafiltration (UF) core technology principle

Using hollow fiber membranes with a molecular weight cutoff of ≥ 10,000 Daltons, the following is achieved through a screening mechanism:

Efficient removal of bacteria, colloids and macromolecular organic matter

Selective separation of protein/dye components (such as electrodeposition paint recovery)

Operating pressure is 60% lower than nanofiltration (NF)

Project implementation pain point analysis

Traditional processes have inherent defects:

Land requirements: sedimentation tanks/flocculation tanks occupy 40% of the plant area

Chemical dependence: annual Coagulant consumption reaches 3-5 tons/thousand tons of water

Solid waste problem: backwash sludge accounts for 5-7% of the treated water volume

Disinfection by-products: risk of trihalomethane generation by chlorine disinfection

Technical advantages of ultrafiltration system

Process innovation

Single-stage membrane filtration replaces coagulation/sedimentation/sand filtration three-unit

Turbidity control ≤0.1NTU, iron content ≤0.01ppm

Operation efficiency

Energy consumption is reduced by 35% compared with traditional processes (0.2-0.3kWh/m³)

Recovery rate ≥95%, sludge reduction 80%

Economic efficiency improvement

Land occupation is reduced by 50%, infrastructure cost is saved by 40%

Membrane life ≥5 years, chemical cleaning cycle >90 days

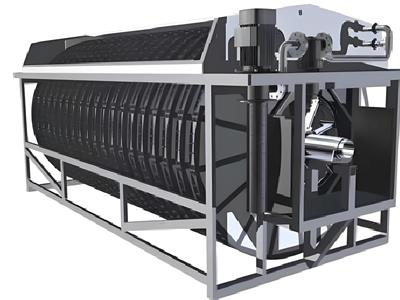

Typical industrial application scenarios

Electrophoretic coating: realize paint-washing water dual-flow recovery

Drinking water quality improvement: direct filtration of surface water (no pre-precipitation required)

High-silicon water quality treatment: interception of colloidal silicon to prevent subsequent membrane pollution