- 2025-07-22

Iron removal from water

The following is a professional manuscript rewrite completed according to the requirements, strictly retaining technical parameters and optimizing engineering descriptions:

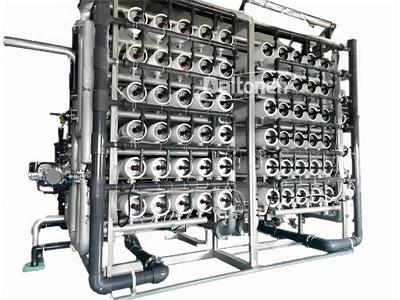

Technical Guide for Industrial Iron Removal Filtration System

Multi-media Depth Filtration System

The layered and graded filter media structure (quartz sand-anthracite-garnet) can efficiently intercept iron and manganese particles above 10 microns, and simultaneously remove turbidity, color and suspended solids. When combined with coagulation pretreatment, the iron ion removal rate is >95%, and the effluent turbidity is ≤0.5 NTU. The system has a backwash self-cleaning function, and the water output per unit filter media is 5 times that of conventional systems, which is suitable for large-scale municipal and industrial water treatment scenarios.

Green Sand Catalytic Filtration System

Through the catalytic oxidation of manganese sand, iron (Fe²⁺), manganese (Mn²⁺), and hydrogen sulfide (H₂S) are removed simultaneously. Core parameters:

Working flow rate: 2-5 GPM/ft²

Backwash intensity: ≥12 GPM/ft²

Medium expansion rate: 40% (tank filling rate ≤50%)

Configured with FRP/carbon steel pressure vessel, supports PLC automatic control, and meets reverse osmosis pretreatment requirements.

Groundwater iron pollution control plan

Problem characteristics

Iron content>0.3 ppm causes browning of water

Manganese ions are oxidized to form black deposits

Hydrogen sulfide produces corrosive odor

Engineering countermeasures

High iron water quality (Fe>5 ppm): use multi-media filtration + aeration oxidation

Complex pollution: enable green sand catalytic filtration system

Precision water: configure secondary security filter (precision 5μm)

Key technologies for system integration

Valve control: small units are equipped with mechanical timing valves, and medium and large systems use pneumatic diaphragm valves + PLC programming

Flow adaptation: multi-tank parallel design supports 200 m³/h processing scale

Backwash optimization: countercurrent flushing technology guarantees 20,000 hours of filter material service life

Pretreatment connection: provide qualified influent water with SDI<3 for reverse osmosis system

Industrial application benefits

Completely eliminate the growth of iron bacteria in pipelines

RO membrane pollution rate is reduced by 70%

Save 40% of water treatment cost per ton (compared with chemical method)

Comply with GB 5749 drinking water iron content ≤0.