- 2025-07-22

Industrial Water Treatment

Industrial water treatment uses a multi-stage series process to achieve precise water control, and four core systems work together:

Boiler feed water treatment system: through ion regulation, TDS is controlled to ≤5ppm, effectively blocking calcium carbonate deposition (deposition rate <0.1mm/year), ensuring the safe operation of high-pressure boilers

Cooling water circulation system: using continuous biological inhibitor addition process, Legionella and other pathogens are controlled to <100CFU/mL, maintaining the heat exchanger end difference ≤2℃

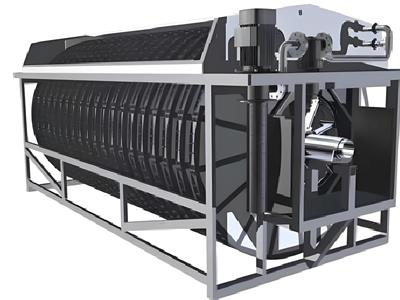

Raw water pretreatment unit: multi-media filter and ultrafiltration membrane combination process ensures that the SDI value is stable <3, providing qualified water for back-end precision treatment

Wastewater deep regeneration system: integrated advanced oxidation + membrane bioreactor technology, achieving CODcr removal rate >85%, stably reaching GB 8978 Level A standard

Industry-specific solutions

Customized process routes based on industry characteristics:

Food and beverage industry: Nanofiltration membrane separation combined with 80℃ pasteurization to achieve a 5-log pathogen removal rate

Energy and power field: Two-stage reverse osmosis coupled with electrodeionization device, output ≥18MΩ·cm ultrapure water

Chemical and pharmaceutical applications: Ozone catalytic oxidation system specializes in difficult-to-degrade organic matter, COD removal rate exceeds 70%

Key technology modules

Hardness control: Food-grade ion exchange resin reduces water hardness to below 0.1GPG

Microorganisms Prevention and control: 254nm UV sterilizer provides 40mJ/cm² irradiation dose

Dissolved oxygen removal: Vacuum degassing tower suppresses dissolved oxygen concentration to the critical point of 0.02mg/L

Project implementation mode

Modular deployment: Containerized integrated design saves 40% of floor space

Intelligent operation and maintenance: PLC+DCS dual control system achieves fault diagnosis response within 10 minutes

Comprehensive benefit indicators

Equipment life cycle: Boiler service life extended by 2-3 times

Resource utilization: Cooling water circulation rate increased to 98%

Compliance guarantee: Fully meet ISO 14001 certification requirements

Operation cost: Reduction of reagent consumption by 30%, sludge treatment cost by 50%