- 2025-07-22

How to Remove Odors from Water

Analysis of the mechanism of odor generation

Hydrogen sulfide pollution: sulfate reduction reaction in anaerobic environment (concentration>0.05mg/L produces rotten egg smell)

Algae metabolites: eutrophic water releases geosmin and 2-methylisoborneol (MIB)

Disinfection by-products: chlorine reacts with humic acid to produce chlorophenols

Pipeline corrosion: iron and manganese bacteria metabolize to produce swamp smell

Three-level odor control system

1. Source pretreatment process

Enhanced coagulation and sedimentation (PAC dosage 20-40mg/L, pH control 6.5-7.2)

Pulsed ozone oxidation (dosage 1.0-3.0mg/L, contact time ≥5min)

2. Selection of core deodorization technology

Activated carbon adsorption system

Coal-based columnar carbon (iodine value ≥ 1000 mg/g, carbon tetrachloride adsorption rate ≥ 60%)

Empty bed contact time (EBCT) ≥ 10 minutes

Advanced oxidation process

Ultraviolet/hydrogen peroxide synergistic device (H₂O₂ addition 2-5 mg/L, UV dose 40 mJ/cm²)

Hydroxy radical generation rate >5×10⁻⁴ mol/L·s

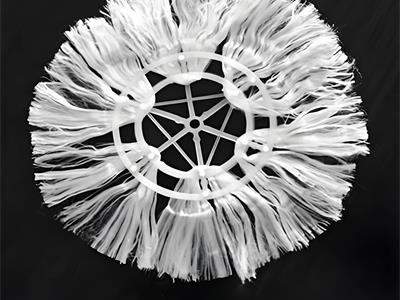

Manganese sand catalytic filtration

KMnO₄ modified filter material (MnOx coating thickness>50μm)

Hydrogen sulfide removal load ≥3g/m²·h

Targeted removal of special pollutants

Geosin/MIB: emergency addition of powdered activated carbon (20-40mg/L)

Chlorophenols: biological activated carbon filter (backwash cycle 24-48h)

Iron and manganese odor: aeration + two-stage contact filtration (dissolved oxygen increased to 6mg/L)

Key parameters for project implementation

Activated carbon filtration rate control: 8-12m/h

Precise control of ozone addition: ORP≥650mV

Residual chlorine maintenance in the pipe network: 0.3-0.5mg/L (inhibit biofilm regeneration)

Water quality compliance verification indicators

Odor threshold (TON) <3 level (GB/T 5750.4 mandatory requirement)

Detection limit of geosmin ≤ 0.00001 mg/L (GC-MS combined analysis)

Residual hydrogen sulfide < 0.002 mg/L (methylene blue spectrophotometry)