- 2025-07-22

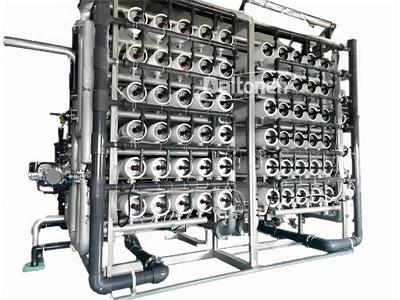

Microfiltration Element

Core filtration characteristics

Filtration accuracy: 1.0-0.1μm (can retain algae/colloids/bacteria)

Working pressure: 0.1-0.3MPa (low pressure difference operation)

Applicable temperature: 5-45℃ (polypropylene material)

Process positioning and configuration

As a pretreatment unit for deep treatment processes such as reverse osmosis and ion exchange:

Effectively reduce the inlet SDI value to <3

Protect the back-end membrane elements from particle fouling

Extend the resin regeneration cycle by more than 30%

Key performance parameters

Initial filtration flux: ≥600L/(m²·h)

Maximum tolerable turbidity: 50NTU (automatic backwash mode)

Microbial retention rate: >99.9% (0.22μm filter element)

Chemical tolerance: pH 2-13 (PVDF material)

Key points of engineering application

System configuration scheme

Multi-stage series design (20μm→5μm→1μm gradient filtration)

Cross-flow filtration mode (concentrated water return rate 15-20%)

Operation and maintenance specifications

Pressure difference control backwash (ΔP≥0.05MPa trigger)

Chemical cleaning cycle: cumulative operation of 200 hours

Terminal integrity detection: bubble point test>0.15MPa

Industry adaptation scenarios

Electronic ultrapure water preparation: pre-stage particle control

Food and beverage production: cold sterilization instead of pasteurization

Biopharmaceuticals: fermentation broth bacterial separation

Circulating cooling water: side filtration system reduces turbidity

Technical advantages

Compared with deep filtration, the flux is increased by 40% and the floor space is reduced by 50%

Modular design meets the treatment needs of 5-500m³/h

Filter element can be replaced online (system shutdown <30 minutes)

Physical separation process without chemical agent addition