- 2025-07-22

Cooling Tower Water Treatment

Core treatment objectives

Control scale index (LSI≤0.5)

Inhibit corrosion rate (carbon steel <0.075mm/a)

Kill microorganisms (total number of heterotrophic bacteria <1×10⁵ CFU/mL)

Key components of the system

Pretreatment unit

Multi-media filter (removal of turbidity>95%)

Weak acid cation exchanger (hardness removal rate ≥85%)

Reverse osmosis system (desalination rate ≥98%, SDI <3)

Water quality stabilization unit

Automatic dosing system (scaling inhibitor/corrosion inhibitor accuracy ±2%)

ORP online monitoring (control range 650-750mV)

Intelligent sewage discharge device (conductivity threshold setting ±50μS/cm)

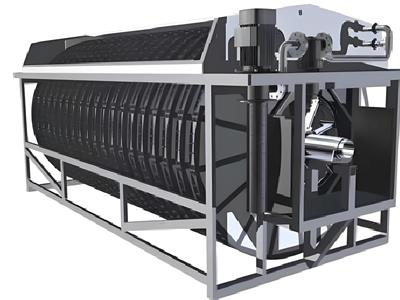

Sidestream treatment unit

High-speed sand filter (pass Filtration speed 40m/h)

Electronic descaling device (output frequency 5-50kHz)

Ultraviolet sterilizer (dose 80mJ/cm²)

Operation control points

Concentration multiple management

Open system: 3-5 times (Cl⁻ balance method control)

Closed system: 5-8 times (softening and desalination are required)

Microbial control

Alternate addition of oxidizing/non-oxidizing bactericides (switch weekly)

Biological sludge control <3mL/m³

Technical benefit indicators

Heat exchange efficiency improvement: condenser tube fouling thermal resistance <3.5×10⁻⁴ m²·K/W

Extended equipment life: copper tube corrosion rate <0.005mm/a

Water-saving efficiency: 97% less water replenishment than DC cooling system

Customized design elements

Material adaptation:

Molybdenum corrosion inhibitor is used in stainless steel system

Copper corrosion inhibitor is required in carbon steel system

Operation mode:

Zero sewage discharge scheme (coupled crystal softening + membrane concentration)

Heat recovery system (enabled when temperature difference >8℃)