- 2025-07-22

Hydrogen sulfide emission reduction

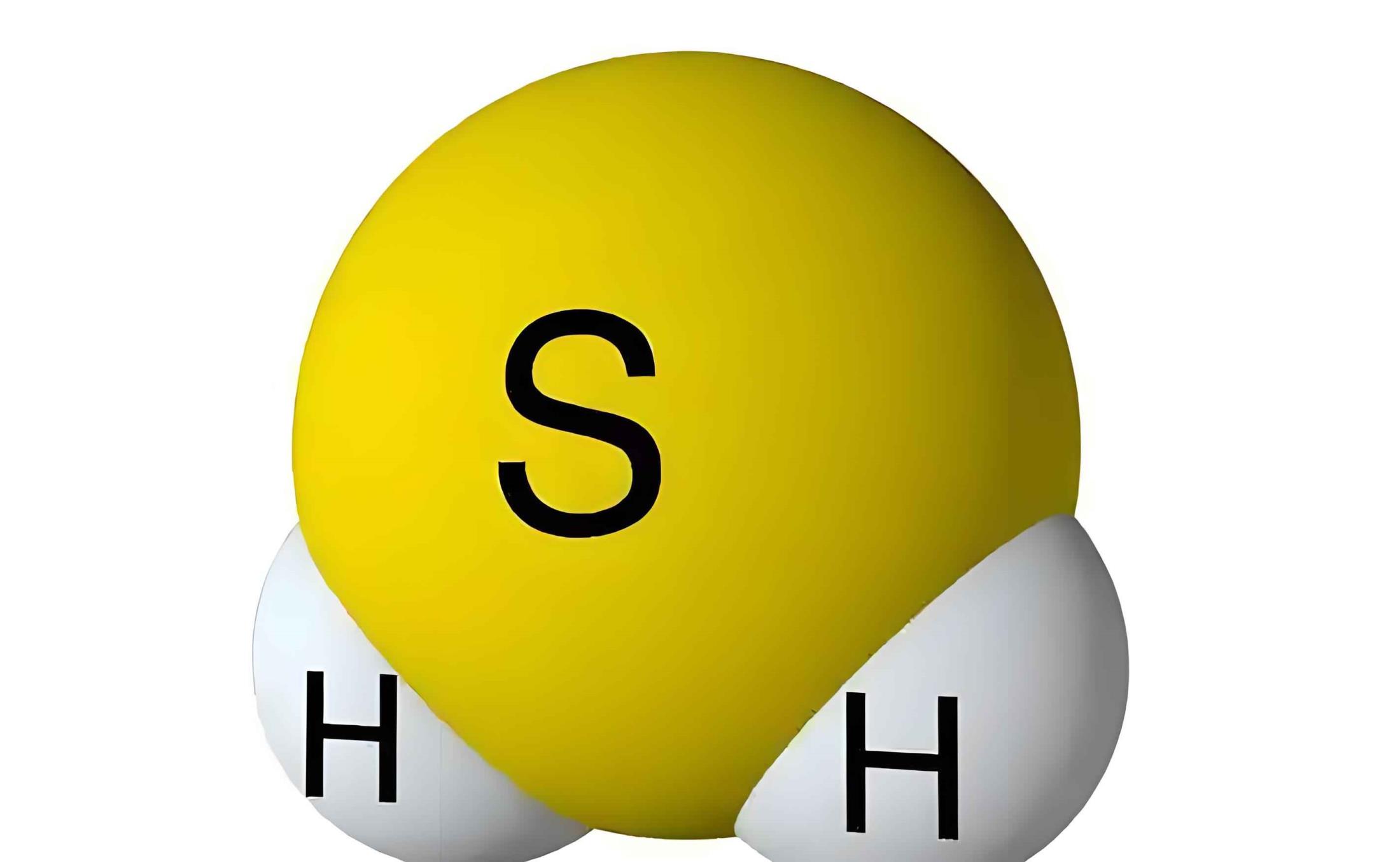

Characteristics and hazards of hydrogen sulfide

Generation mechanism: Sulfate-reducing bacteria (SRB) decompose organic sulfide in an anaerobic environment

Typical scenarios:

Concentration in oilfield produced water reaches 50-200mg/L

Liquid accumulation area of natural gas gathering and transmission pipeline

Main risks:

Explosion limit: 4.3%-46% (volume ratio in air)

Corrosion rate: carbon steel equipment>0.7mm/year (H₂S>20ppm working condition)

Treatment technology solution

1. Green sand filtration system

Working principle:

Use manganese-coated sand filter material (MnO₂ content ≥35%), through redox reaction:

TEXT

H₂S + 2MnO₂ → 2S↓ + Mn₂O₃ + H₂O

Technical parameters:

Applicable concentration: 0.5-10mg/L

Removal rate: 98% (empty bed contact time ≥8 minutes)

Regeneration operation:

5% is required for every 3000 bed volumes treated Regeneration of KMnO₄ solution to restore oxidation capacity

2. Stripping degassing technology

Technical points:

Packing tower design gas-water ratio 15:1~30:1

Henry constant KH=0.385 mol/(L·atm) (25℃)

Emission control:

Tail gas needs to be treated by alkaline solution absorption (NaOH concentration ≥10%)

3. Special chemical agent system

FupengWater H₂S reducing agent characteristics:

Two-component corrosion inhibition-oxidation formula (containing organic amine + peroxy acid salt)

Reaction rate: <30 seconds (H₂S conversion rate 99.2%)

Engineering implementation:

Dosage: 2-8ppm (automatically adjusted according to ORP value)

Equipped with closed filling system to prevent gas escape

Implementation case of an offshore platform

Raw water conditions:

H₂S content: 85mg/L

Iron content: 12mg/L

Solution:

"Green sand filtration + agent synergy" process

Operation effect:

Indicators before treatment After treatment

H₂S 85mg/L Not detected

Iron ions 12mg/L 0.2mg/L

Equipment corrosion rate 1.2mm/year 0.05mm/year