- 2025-07-22

Reverse Osmosis and Nanofiltration

Membrane filtration is the process of separating or removing particles and colloids from a liquid. This process is accomplished by a physical barrier (a semipermeable membrane) that restricts the passage of particles through its pores.

The water entering the membrane module is called the "feed stream".

The liquid that passes through the semipermeable membrane is called the "permeate or product stream".

The liquid on the other side of the membrane containing the retained particles is called the "retentate/concentrate/reject/waste stream".

The more commonly used types of membrane filtration processes are based on the pressure difference across the membrane. These processes include:

1) Microfiltration (MF)

2) Ultrafiltration (UF)

3) Nanofiltration (NF)

4) Reverse Osmosis (RO)

Challenges

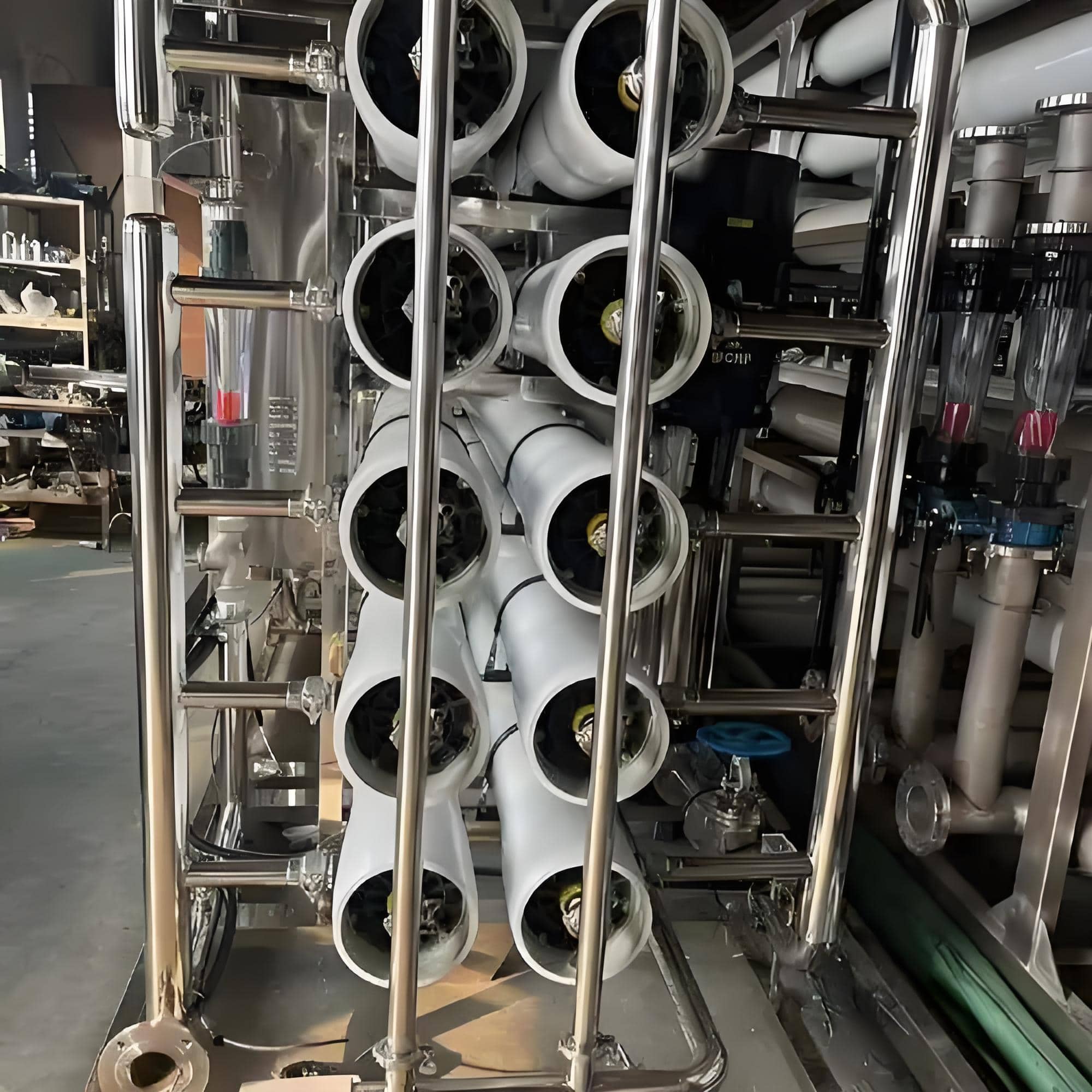

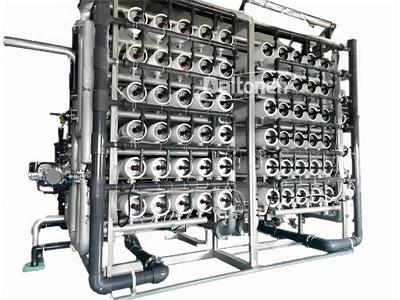

Reverse Osmosis vs. Nanofiltration is a hotly debated topic in the water treatment industry. Proponents of these two membrane filtration technologies have always emphasized the advantages of each water purification system and believe that they each have their own strengths. Reverse Osmosis (RO) and Nanofiltration (NF) systems have similarities in appearance and function. However, nanofiltration systems use newer technology and add some additional features that allow them to perform certain tasks that reverse osmosis systems cannot perform efficiently.

For example, reverse osmosis systems have been found to filter out valuable nutrients that are beneficial to the human body. Nanofiltration systems are designed to prevent this from happening and are far more capable of removing divalent ions that cause water hardness than reverse osmosis systems. Reverse osmosis has been used for a longer period of time than nanofiltration and remains the most preferred choice in applications where the smallest solute molecules such as salt and various monovalent minerals need to be removed.

Solutions

Industrial Applications:

With the development of thin film and composite membranes, the application range of reverse osmosis technology has expanded from traditional seawater desalination processes to various wastewater treatment fields. The application range of reverse osmosis systems includes organic wastewater, electroplating wastewater, metal surface treatment wastewater, pulp and paper wastewater, mining and petrochemical wastewater, textile wastewater, food processing wastewater, radioactive wastewater, irrigation water treatment, municipal sewage, surface water treatment, and contaminated groundwater, especially for the removal of N-nitrosodimethylamine (NDMA) and other organic disinfectant byproduct precursors (DBP).

Nanofiltration has gained much attention for its purpose of softening water and removing various contaminants from drinking water. Nanofiltration can reduce or remove total dissolved solids (TDS), hardness, color, agrochemicals, high molecular weight substances, and fulvic acid substances (which can form trihalomethanes after chlorination). Nanofiltration is also used to remove organic and inorganic substances from different wastewaters. Nanofiltration is an efficient water treatment system suitable for secondary or tertiary wastewater treatment in industry, agriculture, or indirect drinking water reuse.

Conclusion:

The advantages of membrane separation compared to other water treatment solutions are obvious. Although the conceptual processes of nanofiltration and reverse osmosis may be similar, they each have unique factors and uses. Nanofiltration consumes less energy and produces higher flux at low pressure; it is best suited for applications that do not require the feed stream to be completely free of dissolved solids. On the other hand, reverse osmosis is a solution to obtain absolutely pure water, although it consumes more energy to produce.

Advantages

The various membrane filtration processes can be further categorized and compared based on the following categories:

1.) Driving Force

2.) Removal Mechanism

3.) Working Principle

4.) Industrial Applications

This article will focus on Reverse Osmosis (RO) and Nanofiltration (NF); they are the two most commonly used types of membrane filtration. We will now take a closer look at both systems (NF and RO) based on the categories listed above.

1.) Driving Force:

Both NF and RO systems are based on hydraulic pressure to achieve the desired separation, i.e. the transfer of particles through a semi-permeable membrane.

2.) Removal Mechanism:

Unlike Microfiltration (MF) and Ultrafiltration (UF), which are separation processes that rely solely on size exclusion (sieving), NF and RO provide not only size-based separation, but also the ability to adsorb ionic species from the water layer adsorbed to the membrane surface.

3.) Working Principle:

Reverse Osmosis is a filtration process that applies pressure to water, forcing it to pass through a membrane and remove particles and dissolved solids. Water is forced to flow from the concentrated side to the dilute side, while the solutes are retained through the filtration process.

Nanofiltration, often described as a simplified version of RO, uses fewer fine membranes than RO systems. This is reflected in the fact that it requires almost half the feed water pressure of RO systems.

There is considerable overlap in the particle sizes removed by NF and RO. Typically, nanofiltration systems can remove particles as small as 0.001 μm, while reverse osmosis systems can remove particles as large as 0.0001 μm.