- 2025-07-22

Effects of Hard Water

Scale formation mechanism

Hard water precipitates calcium, magnesium and other mineral ions during evaporation, forming stubborn deposits on the surface of the equipment. Commonly found in:

Heat exchanger/boiler heat transfer surface (scaling rate>1mm/year)

Pipeline inner wall (deposition risk doubles when flow rate <1.5m/s)

Bathroom facilities (calcification scar hardness reaches Mohs level 3)

Industrial hazard evidence

Pipeline system

Narrowing of pipe diameter leads to 200-400% increase in pressure loss

Galvanized steel pipe corrosion rate increases by 5 times

Boiler system

1mm scale reduces thermal efficiency by 9-12%

Local overheating causes pipe burst accident (>350℃ pipe wall temperature difference)

Microbial risk

Scale pore formation For Legionella biofilm carrier

Increase the bacterial growth rate in hard water environment by 40%

FupengWater professional solution

Core process

Reverse osmosis system (RO)

Desalination rate> 98% to completely remove scaling ions

Equipped with automatic flushing program to prevent membrane pollution

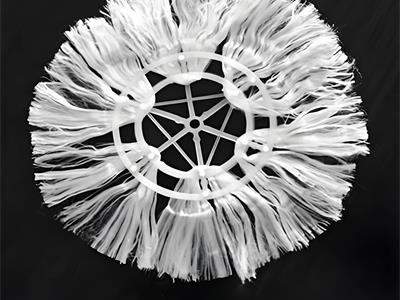

Nanofiltration system (NF)

Selective retention of divalent ions (Ca²⁺/Mg²⁺)

Applicable to medium hardness water sources with TDS≤500mg/L

Engineering benefits

Equipment protection

Extend boiler life by 3-5 years (in accordance with NB/T 47035 standard)

Extend the cleaning cycle of heat exchanger to 12 months

Energy consumption optimization

Boiler fuel consumption is reduced by 15-22%

Pumping system power consumption is reduced by 18%

Operation and maintenance guarantee

Eliminate the need for periodic acid washing of bathroom facilities

Avoid production suspension and cleaning losses (average daily savings> ¥20,000)