The anion bed is an anion exchanger filled solely with anion resins (strongly basic or weakly basic) to absorb anions such as chloride ion, while the cation bed is a cation exchanger filled solely with cation resins (strongly acidic or weakly...

The anion bed is an anion exchanger filled solely with anion resins (strongly basic or weakly basic) to absorb anions such as chloride ion, while the cation bed is a cation exchanger filled solely with cation resins (strongly acidic or weakly acidic) to exchange and absorb cations such as Na+ and Ca+. The mixed bed (high-speed mixed bed) is a mixed ion exchanger filled with both cation and anion resins to remove residual cations and anions in water. The anion and cation regeneration tank is used for the rejuvenation of saturated anions and cations.

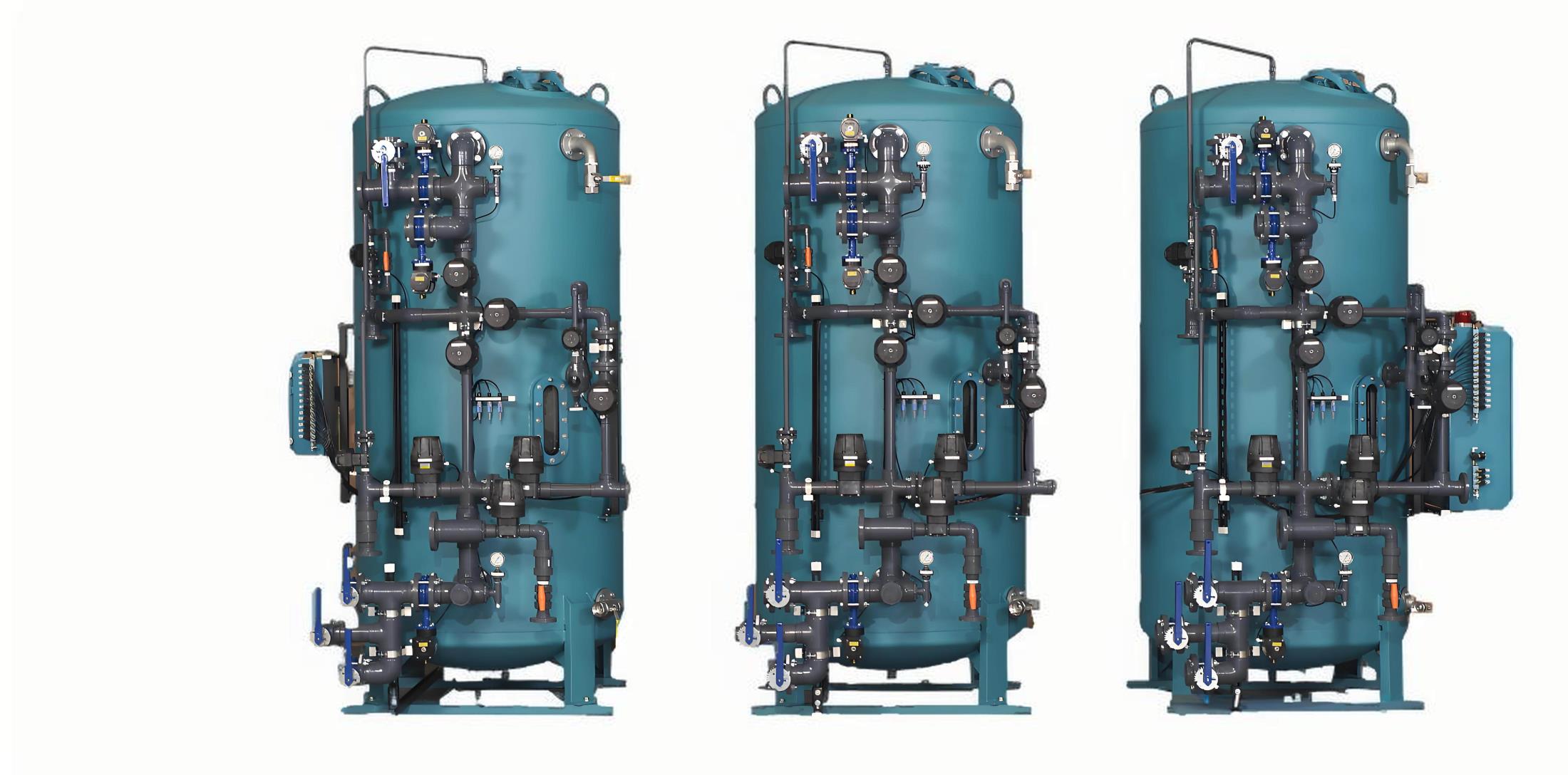

The desalination system consists of a cation exchanger, a degassing tower, an intermediate water tank, an intermediate water pump and an anion exchanger. It mainly plays a preliminary desalination role in the process. After the first desalination, the conductivity of the effluent can be close to 5us/cm. In the process, the cation exchanger exchanges the metal cations in the water with the hydrogen ions in the resin group through a replacement reaction, absorbs most of the cations in the water, and releases hydrogen ions at the same time. The design operating flow rate of the cation exchanger is 10-30m/h, and the maximum designed water output is: 160t/h. The exchanger is equipped with 001×7 styrene series strong acid cation resin. In the process, the anion exchanger mainly removes most of the anions in the water. Through the hydroxyl type anion resin, it absorbs the anions in the water and releases the hydroxide ions at the same time. It combines with the hydrogen ions released by the cation bed effluent to form water molecules, thereby achieving the purpose of desalination. The designed operating flow rate of the anion exchanger is 10-30m/h, the designed maximum water output is 160t/h, and the exchanger is filled with 201×7 strong base styrene series anion resin. The resin in the mixed ion exchanger is 001×7: 201×7=500:1000. The designed water conductivity of the mixed bed is ≤5us/cm, the designed operating flow rate of the mixed ion exchanger is 13-40m/h, and the designed maximum water output is 160t/h.

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD