- 2025-07-16

semiconductor

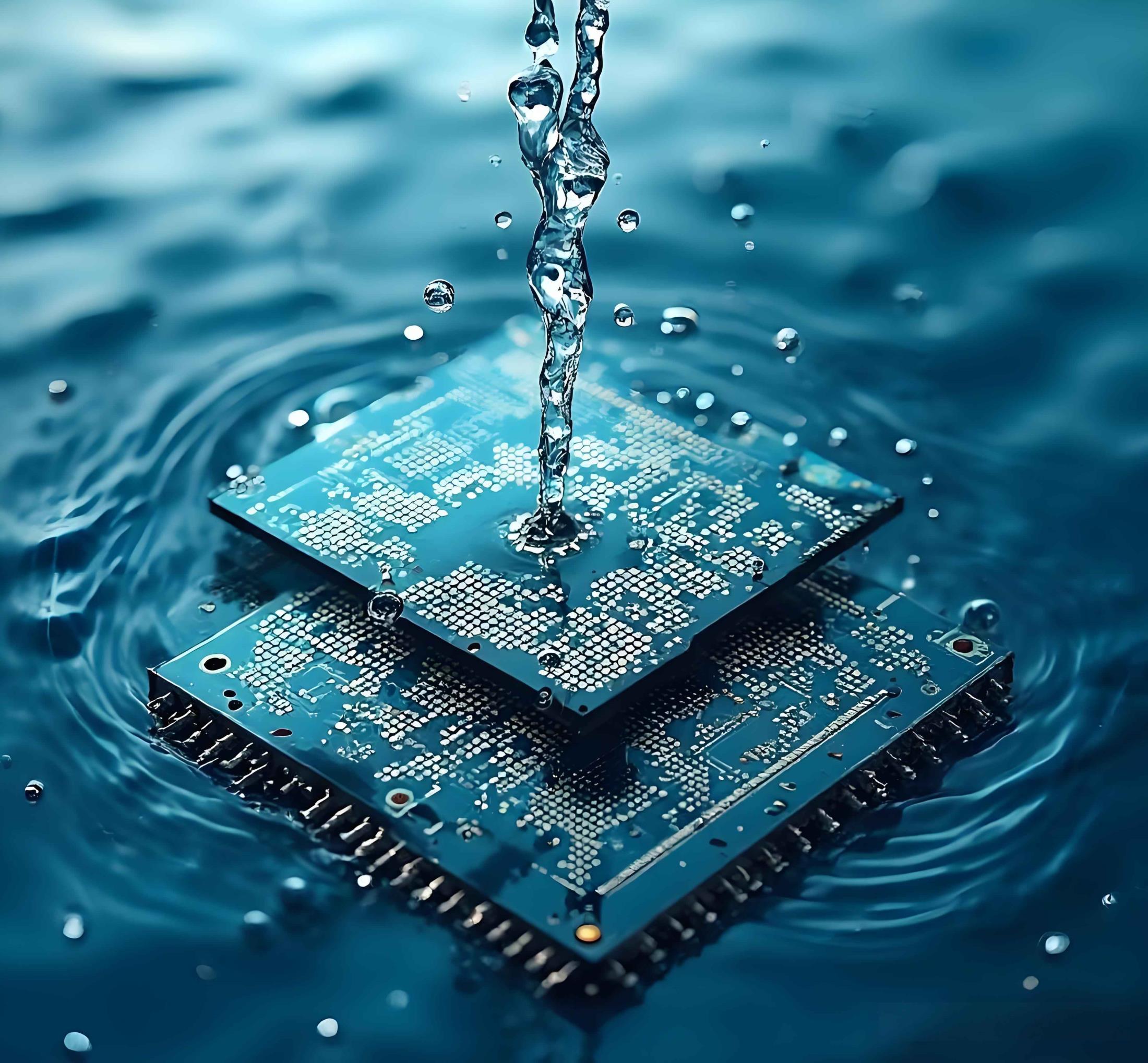

Water Treatment for the Semiconductor Industry | Reverse Osmosis Systems

Semiconductor water treatment refers to the process of purifying and treating water used in the semiconductor industry. Water is an essential component of the semiconductor manufacturing process and its quality and purity are critical to ensuring the reliability and performance of semiconductor devices.

The main purpose of water treatment in the semiconductor industry is to remove impurities and contaminants that may adversely affect the manufacturing process. These impurities include particulate matter, organic compounds, dissolved gases, and ions such as metals and ions. Even trace amounts of contaminants can cause defects in semiconductor devices or affect the performance of integrated circuits.

Our water treatment technologies for the semiconductor industry include:

Nanofiltration Systems

Reverse Osmosis Systems

Water Softeners

Deionized Water Systems

Industrial Ultrafiltration Systems

Semiconductor Water Treatment Methods and Procedures

The following are some of the technologies and processes commonly used in semiconductor water treatment:

Filtration: Filtration is used to remove suspended particles, colloids, and larger impurities from water. Filtration can be achieved through various filtration methods such as activated carbon filters, multi-media filters, microfiltration, and ultrafiltration.

Reverse Osmosis (RO): Reverse Osmosis is a membrane-based process that uses pressure to force water through a semipermeable membrane to remove dissolved impurities, ions, and most organic compounds. RO is effective in removing a wide range of contaminants and is often used as a pretreatment step in semiconductor water treatment.

Deionization (DI): Deionization, also known as ion exchange, involves passing water through a bed of ion exchange resins to remove dissolved minerals, ions, and charged impurities. Deionization is often used after reverse osmosis to further purify the water to high purity.

Ultrapure Water (UPW) Systems: UPW systems are designed to produce the extremely high purity water required for critical semiconductor manufacturing processes. These systems typically combine multiple treatment technologies, including reverse osmosis (RO), deionization (DI), and other advanced purification technologies to achieve the desired water quality.

Advanced Oxidation Processes (AOP): AOP involves the use of strong oxidants, such as ozone or ultraviolet (UV) light, to degrade and remove organic compounds and contaminants that cannot be removed by traditional treatment methods.

Monitoring and Control: Continuous monitoring of water quality parameters, such as resistivity, total organic carbon (TOC), and particulate counts, is critical to semiconductor water treatment. We employ advanced control systems to maintain consistent water quality and ensure compliance with stringent purity standards.

Semiconductor water treatment is a highly specialized field that requires expertise in water chemistry, process engineering, and the specific requirements of the semiconductor industry. The goal is to produce water of the highest purity to meet the stringent standards of semiconductor manufacturing processes and ensure the reliable production of high-quality semiconductor devices.