- 2025-07-22

Marine desalination

Challenges of fresh water supply for ships

Fresh water demand standards for ocean-going ships:

Daily consumption per capita ≥ 100L (including daily life, equipment flushing and power supply)

Traditional water tank configuration: occupies 3-7% of deadweight tonnage, and the loss of tank capacity is 15m³/thousand tons

Core value of marine seawater desalination system:

Real-time water production replaces static water storage (range freedom increased by 100%)

Load optimization: per ton of fresh water reduction equivalent to 1.2 tons of fuel savings/year

Cabin space release rate >18% (can be converted to cargo hold or living area for expansion)

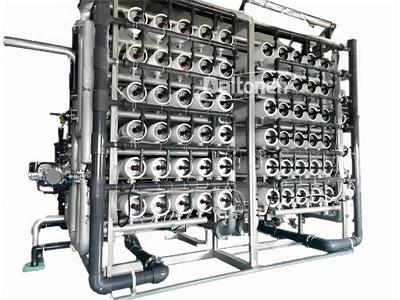

Technical specifications for marine reverse osmosis system

Core components:

Titanium alloy high-pressure pump (corrosion resistance grade ASTM B265 Gr9)

TFC membrane element for seawater (salinity removal rate ≥ 99.4%)

Intelligent energy recovery device (ERD efficiency > 95%)

Operation parameters:

Operating pressure: 5.5-6.8MPa

Water flux: 1.2-3.6m³/h (corresponding to 50-150GPH)

Concentrated water discharge: Salinity increase <15% (in compliance with MARPOL Convention)

Special design:

Anti-roll stabilization system (tilt ≤ 30° continuous operation)

Triple-proof control cabinet (IP66 protection/salt spray resistance 2000h)

Low voltage drive (24VDC adapted to ship power grid)

Engineering verification case

100,000-ton bulk carrier project:

Configured with 2×2.5m³/h units (redundant design)

Annual water saving cost reduced by $84,000 (compared with port water replenishment)

Luxury yacht application:

Integrated equipment (occupying an area of <1.2m²)

Fresh water quality: TDS<200ppm (in line with WHO drinking water standards)

Shipowner core benefits

► Improved economy

Fuel efficiency: ≤3.2kWh of electricity per ton of fresh water produced

Exemption from port water supply fee ($0.8-2.5/ton)

Equipment investment payback period <14 months

► Freedom of navigation

Unlimited navigation area self-sustaining capacity (no need to plan water replenishment port)

Water supply guarantee in extreme weather (wave height ≤7 meters continuous operation)

► Ship maintenance optimization

Equipment flushing water: prevent salt crystal corrosion (extend life by 40%)

Outer shell cleaning: maintain paint adhesion (reduce docking frequency)

► Compact reliability

Modular design: power cabin in-situ replacement (disassembly and assembly <4h)

Self-diagnosis system: membrane pollution warning >72h lead time