The plate-and-frame filter press is an ideal solid-liquid separation equipment for suspensions, characterized by compact design, operational flexibility and reliable performance.

Plate and frame filter presses are widely used for solid-liquid separation in various industries. Their versatility and high solid-liquid separation capabilities have made them popular in fields such as wastewater treatment, pharmaceuticals, food and beverage processing, and chemical manufacturing.

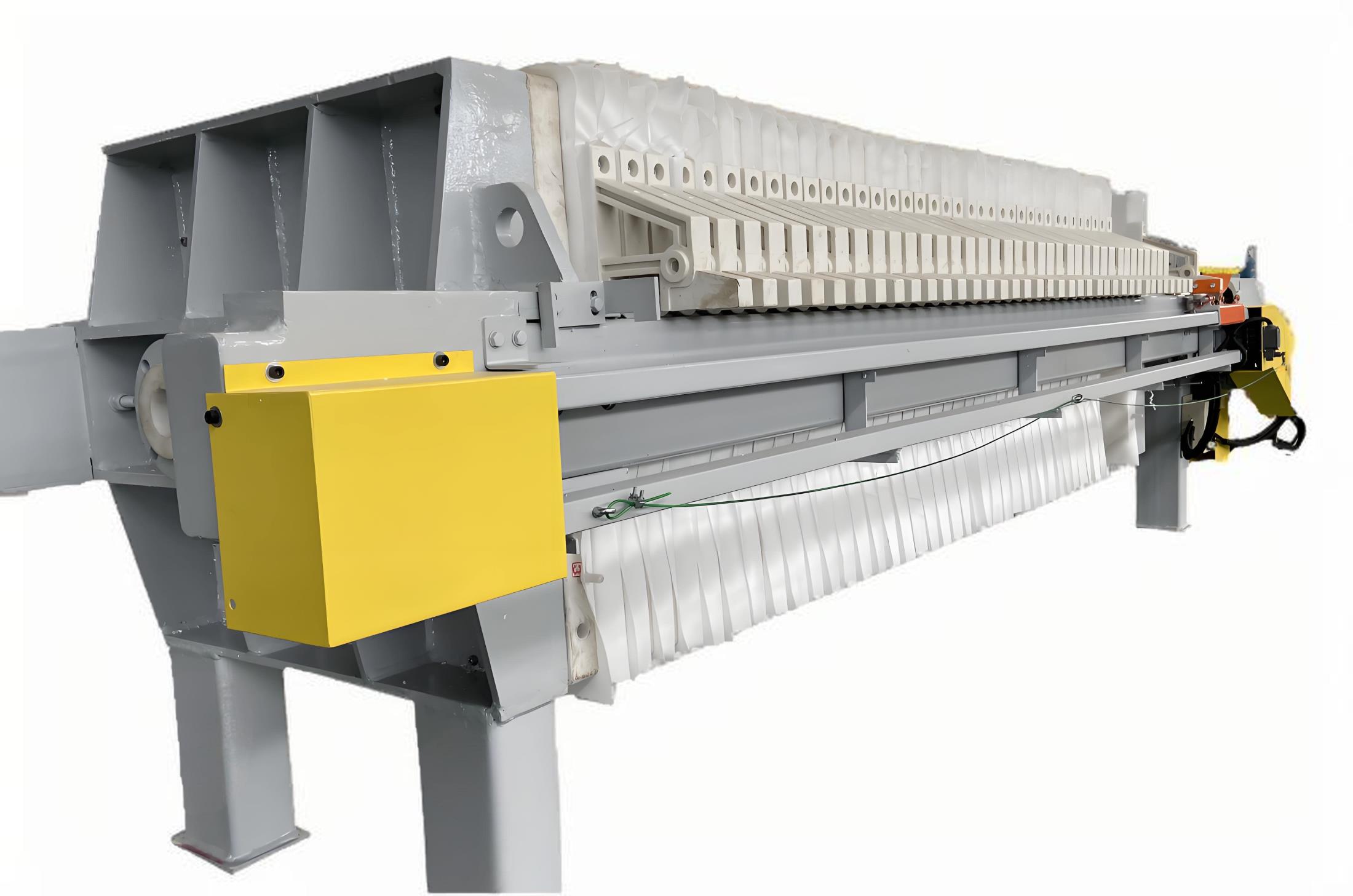

A plate and frame filter press primarily consists of a thrust plate, a pressure plate, filter plates, a filter frame, a crossbeam, filter media (filter cloth), a pressure device, and a sump. The plates and frame are arranged alternately, with filter cloth laid on both sides of the filter plates. A hydraulic cylinder presses the plates and frame together, creating a filter chamber. The filter frame and filter plates have corner holes, forming a complete channel for the introduction of suspension, wash water, and removal of filtrate.

Plate and frame filter presses operate intermittently, meaning they must be stopped to discharge the filter cake before the next batch can begin. The filtration cycle typically ranges from 20 minutes to 3 hours, depending on the characteristics of the filter material. In contrast, vacuum belt filters can operate continuously. If the processing volume is too large, a vacuum belt filter may also be considered.

We offer filter plate sizes of 320, 450, 630, 800, 1000, 1250, 1500, and 2000 mm. We can also customize filter plate sizes based on customer requirements.

Polypropylene (PP)

Stainless Steel 304 or 316L

Cast Iron

The filtration process for a single batch is as follows:

Closing the Filter Plates and Frames: Pressing a button on the PLC control cabinet causes the hydraulic drive to move the movable filter plates until they come to a stop.

Filling: Pump sludge (or slurry) into the filter chambers one by one. Filtration is complete when all filter chambers are filled with filter cake.

Opening the Filter Plates and Frames: Pull the movable filter plates and frame backward to remove them from the first filter chamber. The filter cake will fall from the filter plates/frame under gravity, and the automatic pull-out system will pull the filter plates out one by one.

Filter Cloth Cleaning: Generally speaking, the filter cloth should be cleaned every 15 to 100 batches. A filter press equipped with a filter cloth cleaning system can significantly improve efficiency.

The automatic plate pulling system and filter cloth cleaning system mentioned above are additional features of fully automatic plate and frame filter presses. Compared to conventional filter presses, fully automatic filter presses significantly improve efficiency. The automatic plate pulling system pulls one or more filter plates at a time to remove the filter cake, and the filter cloth cleaning system automatically cleans the filter cloth, significantly reducing time and labor costs.

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD