Rotary Disk Filter (Disk Filter)The fiber disc filter is a filtration equipment for deep sewage treatment. This technology has the advantages of good treatment effect, high effluent quality, and stable equipment operation. It is mainly used for munici…

Disc filters, as microscreens with rotating mesh, reliably remove fine suspended solids. They play a vital role in a variety of applications, including retaining filterable solids in secondary clarifier effluent, reducing phosphorus levels through upstream sedimentation, and providing initial filtration in surface water recovery and UV disinfection applications.

High hydraulic loads, insufficient tank depth, and poor activated sludge settling are the most common causes of suboptimal secondary clarifier performance. Secondary clarifiers often cannot consistently achieve the required solids retention. Floc overflow increases chemical oxygen demand (COD), biochemical oxygen demand (BOD), and phosphorus loading in both effluent and receiving waterways, leading to increased wastewater treatment costs.

Subsequently installed filtration systems are a fast and effective solution for separating suspended solids, such as sludge flocs. Microscreens, combined with initial sedimentation and flocculation, offer an easy-to-use method for reducing phosphorus concentrations in wastewater to extremely low levels. This helps prevent eutrophication and excessive growth of algae and aquatic plants.

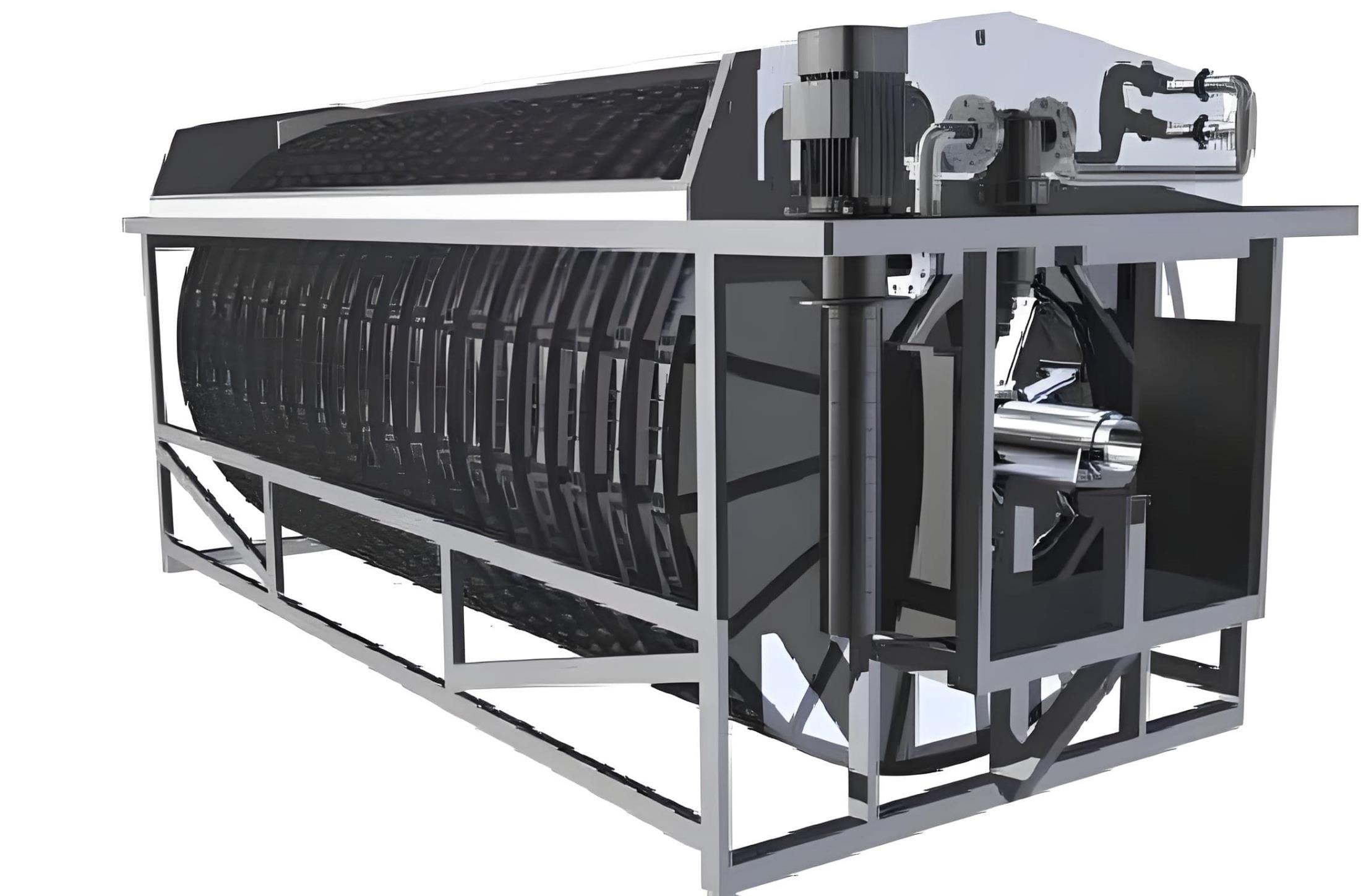

Our disc filters are filtration devices consisting of up to 35 vertical discs mounted on a horizontal shaft. During operation, up to 65% of the disc surface is immersed in the filtrate.

Each disc is composed of 12 individual plastic segments, each equipped with two filter plates. Both sides of the filter plates are covered with filter screens, which are secured by a heat treatment process. If the screens become damaged, each segment can be replaced individually. The finest filter screen size is as small as 10 microns.

Due to its compact footprint and modular design, disc filters can be customized to any specific site requirements.

The disc filter is a gravity-flow filtration system. Wastewater to be treated flows into a horizontal shaft and then into the filter discs through an opening, where water flows outward from the inside of the discs. During the initial filtration process, the discs are stationary. Solid matter is trapped on the inner surface of the discs, gradually clogging the screens and generating an increasing pressure differential. The overflow weir ensures the water level in the tank remains nearly constant. As clogging increases, the upstream water level continues to rise.

When the preset maximum differential pressure is reached, solids are automatically removed from the filter surface. The filter material is cleaned by a nozzle bar. The filter discs rotate slowly, and high-pressure water jets flow from the inside of the discs outwards through the filter screen, removing solids. No fresh water is required, as the filtrate can be used for backwashing. The spray water, along with any entrained solids, is collected in a trough and drained axially out of the machine. The filtration process continues while the discs are cleaned.

Biological Wastewater Filtration: Disc filters are commonly used to separate fine suspended solids from biological wastewater in municipal and industrial applications. They are particularly suitable for applications where secondary clarifiers are undersized or have poor activated sludge settling performance, making them inefficient. Our disc filters consistently achieve effluent specifications far exceeding filterable solids limits and significantly reduce phosphorus concentrations. 2. Filtration to protect or improve the efficiency of downstream treatment systems: A virtually solids-free stream is a prerequisite for efficient, maintenance-free operation of subsequent treatment steps (such as UV disinfection or membrane filtration). Our microscreens significantly reduce suspended solids concentration, resulting in cost savings for downstream systems that offset investment and operating costs.

Industrial Water and Wastewater Treatment: New regulations require advanced wastewater treatment at the source for direct or indirect discharge. Wastewater recycling also requires solids removal, as service and process waters must be virtually solids-free.

Special Applications: These include wastewater treatment in the paper and pulp industry, wastewater treatment in the plastics processing industry, treatment of service and process water to close the water cycle (for example, in the food and chemical industries), and microplastic removal.

Small footprint with high hydraulic throughput capacity.

Gravity-fed systems offer low head loss and eliminate the need for wastewater lifting.

Excellent removal of filterable solids, COD, BOD, and phosphorus. 4. Ensures compliance with discharge standards and reduces wastewater discharge costs.

The mesh is locked in shape and heat-set for chemical resistance.

Because filtrate is used for cleaning, no external water supply is required.

Can be installed in a stainless steel tank or the customer's concrete tank.

Continuous operation is possible, even during backwashing.

Individual filter elements are easily replaced without the need for lifting equipment.

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD