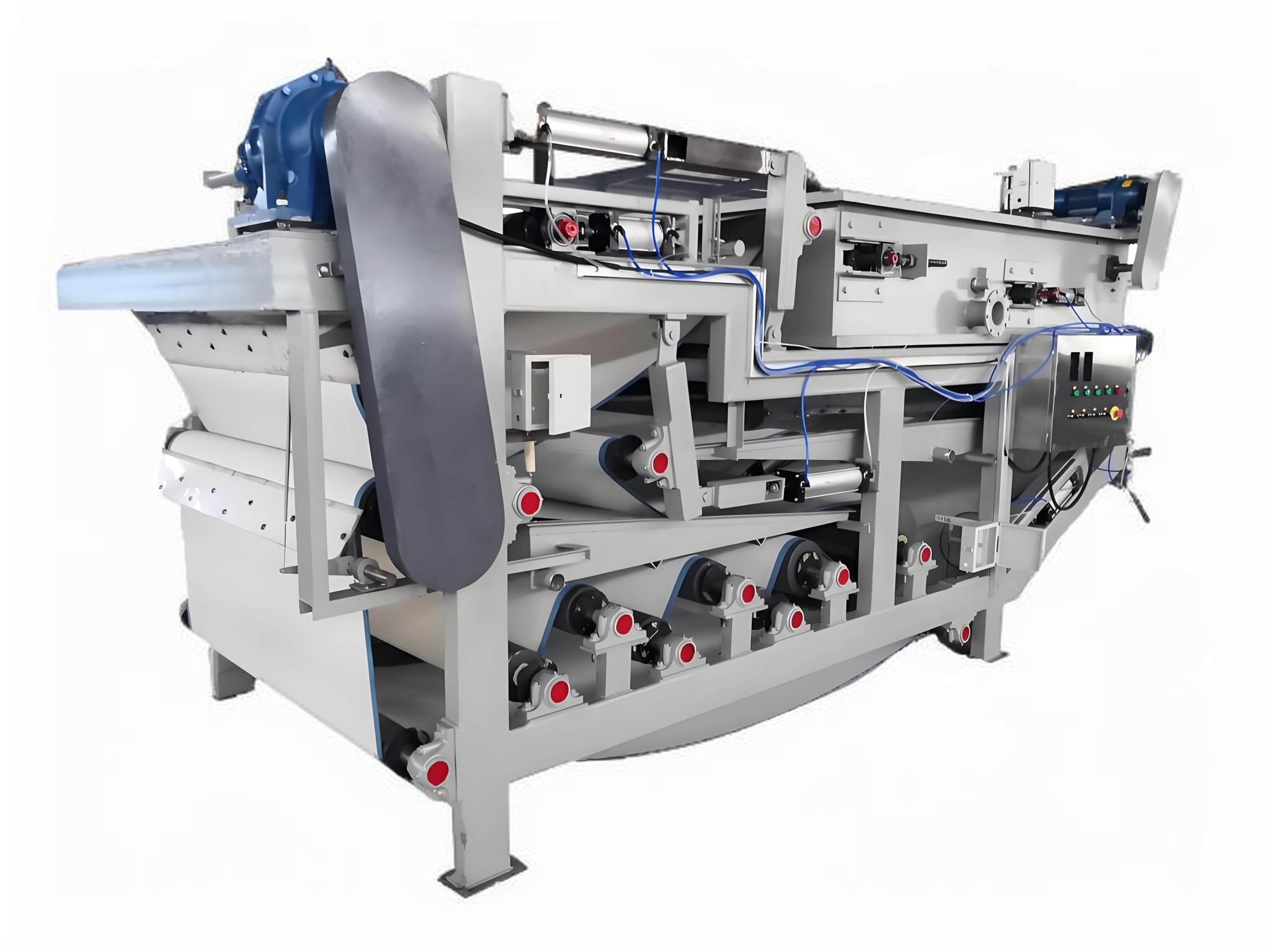

Thickening and Dewatering Integrated MachineDYN series sludge thickening and dehydration machine is a new type of efficient and continuously operated solid-liquid separation equipment. It uses polyester mesh as the filter medium, and can dehydrate var…

A concentrator and dewatering machine is a type of wastewater treatment equipment that integrates the concentrating and dewatering processes into a single unit to reduce sludge volume. Equipment like belt filter presses and screw presses can process a variety of sludges from various industries, including municipal wastewater, papermaking, and the chemical industry, providing an efficient and economical solution for solid-liquid separation.

Sludge Conditioning: The incoming sludge is mixed with polymers to form larger, more easily separated clumps called flocs.

Concentration: In the initial stage, typically using a rotating drum or a series of drums, the conditioned sludge is subjected to gravity or centrifugal force, separating the bulk of the liquid.

Dewatering: The concentrated sludge then enters the dewatering stage, where the mechanical pressure generated by the drums or screws further compresses the sludge, squeezing out more liquid and ultimately forming a drier, solid "sludge cake."

Filtrate and Cake Discharge: The separated liquid (filtrate) is discharged, and the dewatered sludge cake is subsequently removed from the machine.

Belt Filter Press (BFP): This machine uses a pair of filter belts to press the sludge through a series of rollers to achieve dewatering.

Screw Filter Press: This machine uses a screw mechanism to propel the sludge through progressively smaller spaces, increasing pressure and achieving effective dewatering.

Decanter Centrifuge: This high-speed rotating device uses centrifugal force to separate solids and liquids from the sludge.

Reduced Costs: By integrating two processes into one unit, these units eliminate the need for separate thickening and storage systems, reducing construction and operating costs.

Improved Efficiency: The integrated design simplifies the sludge treatment process, allowing for direct processing of low-concentration sludge, while also reducing overall floor space. 3. Improved Performance: Modern equipment incorporates advanced features like automatic pressure regulation and self-cleaning, ensuring consistently high-quality treatment results.

Versatility: All-in-one equipment is suitable for a wide range of industries, including municipal wastewater, chemicals, papermaking, and food and beverage.

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD